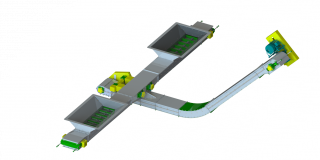

Sukup Drag Conveyors offer a reliable and more cost-effective solution for transporting grain. Designed with precision and efficiency, these conveyors are tailored to meet the challenging demands of material handling. Its galvanized construction and replaceable components, including bottoms, liners, rails, and rollers, ensure long-lasting performance even in high-capacity operations. The conveyor is gentle on grain, minimizing damage during transport and maximizing grain quality. Sukup Drag Conveyors are also customizable to fit your operation and material handling needs.

A standout feature of the Sukup Drag Conveyor is its removable bearing, sprocket, and shaft assembly. This innovative design allows the entire unit to be removed without separating the shaft from the bearings or sprockets, simplifying maintenance and reducing downtime. Additionally, the patented conveyor covers are exclusive to Sukup, requiring fewer tools for installation and eliminating the need for sealants while keeping dust in and water out.

To further extend its lifespan, the conveyor offers standard 7-gauge bottoms with optional abrasion-resistant bottoms available in 3/16", 1/4", and 3/8" thicknesses. With its high-quality construction, smart design, and replaceable components, the Sukup Drag Conveyor is a reliable choice for both small and large-scale material handling needs.

Standard Features

- Exclusive, patented cover design keeps dust in and water out (U.S. Patent #8,047,358)

- Cover clamps ensure that the cover locks tight to the body

- Bearing, sprocket, and shaft can be removed as an entire assembly, saving time

- Removable bottom can be easily replaced without replacing the entire body of the conveyor

- Externally-mounted, heavy-duty pillow block bearings on head and tail

- Heavy-duty construction throughout means Sukup Drag Conveyors will last for years to come

- Turned, ground, and polished shaft

- 1/2" UHMW paddles eliminate steel-to-steel contact

- Up to 10˚ incline allowed with double flighting

- Corrosion-resistant Acme thread take-up screws at tail

- Split sprockets standard on some larger capacity conveyors

- Up to 60,000 bu/hr.

Product Accessories

- Abrasion-Resistant Liners on sides are offered in 10 gauge and 3/16"

- Abrasion-Resistant bottoms are available in 3/16" and 1/4" thicknesses

- End relief Door prevents damage to the conveyor in the event of a discharge plug

- Rail Return comes standard on 21" wide or wider conveyors. Optional on 12" and 16" wide conveyors

- Reversing Feature can take grain in multiple directions and is a great addition if you are looking to unload into two separate bins

- By-pass drive-over hoppers have an adjustable shroud to control flow and are available in 6', 8' or 10' lengths in standard or low-profile designs using combinations of hopper can achieve pit lengths up to 50'

- By-pass inlet hoppers are available in 2', 3', and 4' lengths

- Intermediate discharge gates can act as a separate discharge location from the head and are made up of 7 gauge construction

Product Features

- Extremely Gentle on Grain

- Patented Self Sealing & Easy to Remove Covers

- Maintenance Friendly Head & Tail Sections

- A/R Lined Return Rails

Venedocia, OH